Advancements in 3D Printing Technology: All You Need To Know

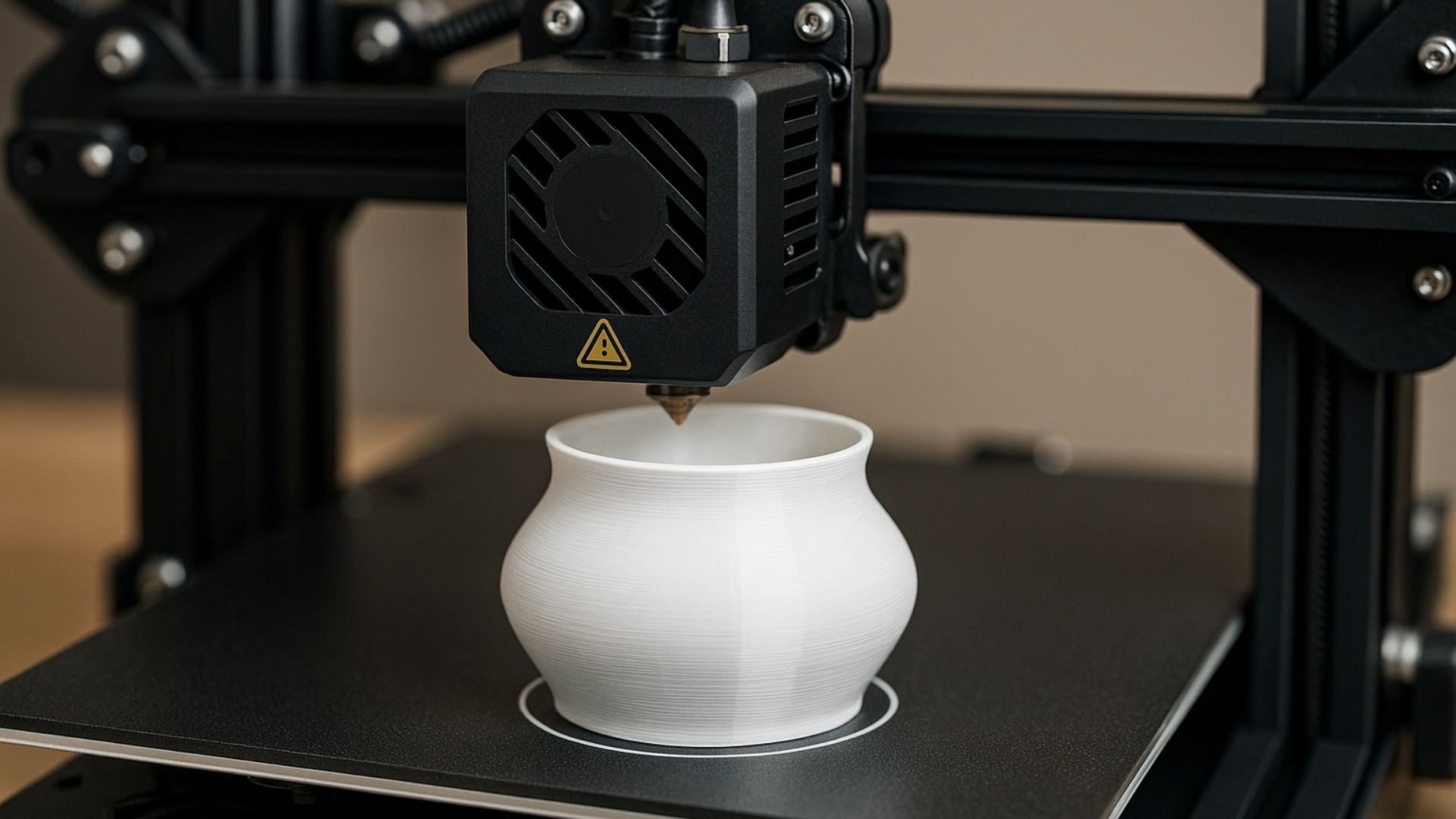

3D printing technology has made amazing strides in the last few years, changing the world of manufacturing and innovation. This article goes into detail about the interesting history of 3D printing, the many ways it can be used, and how it has changed many industries.

The idea of 3D printing, also called additive manufacturing, goes back to the 1980s. Since then, it has come a long way from where it started. 3D printing machines from the past were big, expensive, and not very useful. But improvements in 3D printing technology have made machines easier to use and more flexible, which has made 3D printing a household name.

Table of Contents:

Different Types of 3D Printing Technologies

Many different kinds of 3D printing technologies exist, and each creates things in three dimensions in its own way. Some of the most popular ways to print in 3D are:

Fused Deposition Modeling (FDM)

FDM is a very common way to make 3D prints. It creates objects by pushing out layers of thermoplastic filament. PLA and ABS are two common materials used in FDM printing. For beginners and hobbyists who want to learn how to 3D print, Flashforge makes a number of different types of FDM 3D printers, including the Adventurer 5M Pro (AD5MP) and the Adventurer 5M (AD5M).

Stereolithography (SLA)

A UV laser or other light source cures (solidifies) a liquid photopolymer resin used in SLA. It makes objects that are very smooth and detailed, and manufacturers often use it to model jewelry and teeth.

Digital Light Processing (DLP)

DLP is like SLA in that it uses a digital light projector to cure an entire layer of resin at the same time. It can be faster than SLA and manufacturers also use it to create prints with a lot of detail.

Selective Laser Sintering (SLS)

Selective Laser Melting (SLM)

SLM works at higher temperatures than SLS, but they are similar. It melts metal powders, which manufacturers usually use to create strong metal parts.

Electron Beam Melting (EBM)

Binder Jetting

When you binder jet, you put a liquid binding agent on a powder bed in a specific way. People often use this method to create big things and parts in full color.

Material Jetting

Material jetting uses several print heads to place and cure drops of photopolymer materials. It can make things with high resolution and many colors.

Laminated Object Manufacturing (LOM)

LOM makes things by stacking and gluing sheets of material (usually paper or plastic) together and then cutting them into the right shape with a laser or knife.

Direct Energy Deposition (DED)

DED is the process of putting down material, usually powder or wire, through a nozzle that a high-energy source, like a laser or electron beam, melts. Manufacturers use it to fix and add material to parts that are already there.

Continuous Liquid Interface Production (CLIP)

Materials Used in 3D Printing

3D printing materials are important parts of the additive manufacturing process, and they are very important for figuring out what 3D-printed objects can do and what they are made of. There are now a lot more materials you can use for 3D printing. At first, 3D printers could only work with plastics. Now they can also work with metals, ceramics, and things that break down naturally. This variety makes it possible to create complex and useful things. Many different types of materials can be used for 3D printing. Here are some general categories of these materials:Thermoplastics

• PLA (Polylactic Acid): PLA is a very common material for 3D printing. It’s easy to use and can be used for a lot of different things. It comes in a range of colors and can break down naturally.

• ABS (Acrylonitrile Butadiene Styrene): ABS is a strong and long-lasting material. People often use it to make functional prototypes and parts, but it needs a heated print bed because it tends to warp.

• Nylon: Nylon threads are strong and flexible, which is why people use them. They can be used for a lot of different things, like making functional prototypes and mechanical parts.

• Polycarbonate: Polycarbonate is a strong, heat-resistant plastic that manufacturers use for parts that need to stay stable at high temperatures and resist impacts.

• PETG (Polyethylene Terephthalate Glycol): PETG is a tough and hard material that manufacturers often use in 3D printing. It can handle a lot of different chemicals and can be used for a lot of things.

• TPE (Thermoplastic Elastomer) and TPU (Thermoplastic Polyurethane): These flexible filament materials are used to make soft, rubber-like things like phone cases and shoe soles.

Thermosetting Polymers

• Resins (for SLA and DLP): These liquid photopolymer materials harden when exposed to UV or other light sources. They have a smooth finish and great detail. Different kinds of resins exist, such as standard, flexible, and tough.

Other Materials

• Metal Alloys: Metal 3D printing technologies like SLS, SLM, and EBM use different metal powders, such as aluminum, titanium, and stainless steel. Manufacturers use them in the medical, automotive, and aerospace fields.

• Ceramics: 3D printing with ceramics uses materials like alumina and zirconia, which make things that can withstand high temperatures and don’t conduct electricity.

• Wood Filaments: These materials are made of PLA and wood fibers, which lets you create 3D-printed things that look and feel like wood.

• Biodegradable and Sustainable Materials: Some 3D printing materials, like bioPLA and hemp-based filaments, are good for the environment and break down naturally, so they can be used in applications that care about the environment.

• Carbon Fiber-Infused Filaments: Manufacturers make these filaments by mixing thermoplastics with carbon fiber. This makes 3D-printed parts that are stronger and stiffer.

• Polyvinyl Alcohol (PVA): PVA is a common support material in dual-extrusion 3D printing because it dissolves in water, which makes it easy to take out of complicated designs.

• Composite Materials: Composites are made by mixing two or more types of materials to get certain properties. For instance, carbon fiber composites are used to make important parts that are light.

The type of material used for 3D printing depends on the use, the desired properties, and the specific 3D printing technology used. Choosing the right material to get the results you want, whether you’re making prototypes, functional parts, or works of art, is very important.

Applications Across Industries

3D printing can be used in many different fields because it is so flexible. It has changed the way businesses work in many ways, from quick prototyping in engineering to making custom prosthetics in healthcare. The fashion, jewelry, and architecture industries have also adopted the technology.Medical Applications of 3D Printing

3D printing has changed a lot of fields, including medicine. These are some of the amazing things that 3D printing can do in medicine:

• Prosthetics: 3D printing has made it possible to create custom prosthetics. These will provide greater comfort for the patient because they fit perfectly.

• Bioprinting: Bioprinting is a type of 3D printing that uses cells, bioinks, and biomaterials to make biomedical parts that look and feel as much like natural tissue as possible. This technology could be used to replace organs that are sick or damaged.

• Dental Applications: 3D printing has made it possible for dentists to make crowns, bridges, stone models, and a variety of orthodontic appliances with great accuracy and speed.

• Custom Surgical Tools: We can make custom surgical tools with a 3D printer for specific surgeries. Compared to old ways, they cost less and can be made faster.

• Medical Models: 3D printing can create exact copies of patients’ body parts that surgeons can use to plan and practice surgeries. This can lead to better outcomes.

• Customized Implants: We can customize implants to fit a patient’s body better, which makes them work better with the body and causes fewer problems.

• Drug Delivery Devices: 3D printing makes it possible to create complicated shapes, which allows for the creation of drug delivery devices that can release drugs at a set rate.

• Hearing Aids: We can now 3D print the whole shell of a hearing aid. This cuts down on the time it takes to make them and lets you get a comfortable, custom fit.

• Personal Protective Equipment: When there weren’t enough of them during the COVID-19 pandemic, 3D printing was used to make personal protective equipment for healthcare workers.

• Tissue Engineering: 3D bioprinting creates fake tissues that can be used to test drugs and may be able to fix damaged tissues in the body.

3D printing has a bright future in medicine. It could make patient care better and lower medical costs.

3D Printing in the Aerospace Industry

In the aerospace industry, 3D printing is also very important. Here’s how manufacturers have used it:

• Rapid Prototyping: 3D printing is a cheap and quick way to make prototypes. It lets aerospace engineers make and test designs without having to buy expensive tools or machines.

• Complex Parts: 3D printing can make complicated parts that would be hard or impossible to make with traditional methods. For instance, GE Aviation has used 3D printing to make jet engine fuel nozzles that are lighter and last longer than those made in the past.

• Customization: Aerospace companies can use 3D printing to make parts that are just right for a certain aircraft or spacecraft. This can be very helpful for making parts for older planes that are no longer being made.

• Less Waste: Traditional ways of making things often involve cutting away extra material, which creates a lot of waste. Adding material only where it’s needed with 3D printing cuts down on waste.

• On-Demand Production: 3D printing can make parts as needed instead of in big batches. This can lower the cost of storage and make supply chains work better.

• In-Space Manufacturing: NASA and other space agencies are looking into using 3D printing to make things in space. This could mean that parts could be made in space instead of being sent there from Earth.

3D printing has a lot of advantages, but problems with using it in aerospace also exist. Some of these are the need for high-quality materials, the fact that 3D printing is slower than traditional manufacturing methods, and the need to inspect and process printed parts after they are made. The use of 3D printing in aerospace will keep growing, though, as technology keeps getting better.

Advancements in Automotive Manufacturing Through 3D Printing

The automotive industry has made a lot of progress in the last few years, and one of the most important technologies behind these changes is 3D printing. 3D printing has changed the way cars are designed, built, and tested. Here are some ways that 3D printing is helping the automotive industry move forward:• Designing and Prototyping: 3D printing lets car engineers quickly make and test different parts and designs. This technology lets them quickly make physical models of parts like engine parts, interiors, and exterior panels, which speeds up the process of coming up with new designs.

• Lightweighting: More and more, car makers are using 3D printing to make parts and structures that are lighter. This is especially important for electric vehicles (EVs) because lowering their weight can increase their range and efficiency. With 3D printing, you can make shapes that are too complicated to make with regular manufacturing methods.

• Customization: Customization is becoming more popular in the auto industry, and 3D printing makes it easier to make cars that are unique to each customer. Customers can choose from a variety of interior trims and badges, or they can even design their own parts, which can be 3D printed to order.

• Making Spare Parts: 3D printing changes the way car companies handle their spare parts supply chains. Manufacturers can 3D print parts on demand instead of keeping large stocks of spare parts. This cuts down on storage costs and lead times. This is mostly helpful for classic cars or rare models where it might be hard to find replacement parts.

• Tooling and Manufacturing Aids: Manufacturers use 3D printing to make parts for vehicles and to make custom tools and manufacturing aids. This could include jigs, fixtures, and tools for the assembly line that are made to fit the needs of a certain production process. It makes manufacturing easier and cheaper.

• Complex Geometries: With 3D printing, you can make structures that are very complicated and very well optimized. This is helpful for making parts like heat exchangers, exhaust manifolds, and air intakes, where complex designs can make a big difference in how well they work.

• Electric Vehicle (EV) Advancements: The shift to electric vehicles brings new problems for designing powertrains. 3D printing can make special parts for electric vehicles (EVs), like motor housings and battery pack parts, that need to be both light and good at keeping heat in.

• Sustainability: 3D printing can be a more environmentally friendly way to make things than traditional methods because it often makes less waste and can use recycled materials. This fits with the automotive industry’s growing focus on sustainability.

• Rapid Prototyping for Self-Driving Cars: Building self-driving cars needs a lot of testing and prototyping. 3D printing speeds up the making of custom sensor mounts, brackets, and other test equipment, which helps to move autonomous vehicle technology forward.

3D printing is a key part of the automotive industry’s ongoing evolution. It makes things more efficient, lets people customize things, and helps make cars that are better for the environment and more advanced. As this technology gets better, we can expect even more cutting-edge new ideas in the car industry.The Impact of 3D Printing on Consumer Goods

3D printing has changed the consumer goods industry by opening up new ways to design, personalize, and quickly make things. This technology is changing how people think about, make, and deliver consumer goods. 3D printing is having a big effect on the consumer products industry in these ways:• Customization: One of the best things about 3D printing for consumer goods is that it lets you make products that are very unique and tailored to your needs. Customers can choose the design, color, size, and other features of the things they buy, like clothes, jewelry, shoes, or home decor. Customers may be happier and more loyal because of this personalization.

• Prototyping and Design Iteration: Product designers and inventors can quickly make prototypes and improve their designs, which cuts down on the time and money needed to get a new product to market. This is mostly good for small businesses and startups that need to use traditional manufacturing facilities.

• Short-Run Production: 3D printing makes it possible to make things quickly and cheaply, so you don’t have to do big, expensive production runs. This makes it easier for companies to try out new products or test the market with small amounts.

• Spare Parts and Repairs: 3D printing lets people make new parts for things that would otherwise be thrown away, which makes them last longer. This is especially useful for items that are no longer made or are hard to find, like vintage and rare items.

• Unique Art and Collectibles: 3D printing lets artists and collectors make one-of-a-kind sculptures, art pieces, and collectibles. It makes it possible to make complex and unique things that were hard or impossible to make with traditional methods.

• Home Decor and Furniture: Manufacturers are starting to use 3D printing in the making of home decor and furniture. People can order furniture, lighting, and other home accessories that are made to fit their spaces perfectly.

• Footwear and Apparel: The fashion industry is using 3D printing to make shoes and clothes that are just right for each person. People can get shoes that fit their feet perfectly or clothes that fit them perfectly, which makes them more comfortable and fits better.

• Personal Electronics Accessories: 3D printing can make one-of-a-kind phone cases, headphone stands, and other personal electronics accessories. This lets people show off their style and tastes through the gadgets they use.

• Healthcare and Dental Products: Manufacturers are using 3D printing more and more to make custom dental implants, orthodontic devices, hearing aids, and prosthetics that fit perfectly and are comfortable for each patient.

• Home Improvement: People can use 3D printing to make new parts for tools, appliances, and home improvement items. This DIY method makes repairs easier and cuts down on waste.

• Educational Tools: 3D printing is becoming a useful tool for learning because it lets students make real things and learn about design, engineering, and manufacturing.

• Eco-Friendly Products: Some businesses make eco-friendly consumer goods with as little waste and environmental impact as possible by using sustainable materials and 3D printing.

3D printing is changing the consumer goods industry by giving people more options for personalization, new ideas, and eco-friendliness. As technology gets better, we can expect even more interesting and varied uses in this field. This will give consumers more options and products that are made just for them. For those in the region, a 3D Printing Service Malaysia offers convenient access to these advancements, and if you are looking for a reliable Malaysia 3D Printing Service it is becoming easier to find.The Role of AI in 3D Printing

Artificial Intelligence (AI) is becoming more and more important for improving the capabilities and speed of 3D printing technology. Here are some important ways that AI is helping the field of 3D printing:• Design Optimization: AI algorithms can look at complicated data to make 3D-printed designs better. AI can come up with designs that work and are efficient by taking into account things like how much material is used, how strong the structure is, and how to make it lighter. These improved designs can make parts that are lighter, stronger, and use fewer resources.

• Generative Design: Generative design uses AI to make design options based on parameters set by the user. AI algorithms can create many different versions of a design, giving engineers and designers the chance to look into new and often strange solutions that they might not have thought of otherwise. This method is very useful for complicated parts and products that are made to order.

• Quality Control: AI is used for quality control in 3D printing processes in real time. Machine learning models can keep an eye on the printing process, find flaws or changes from the desired outcome, and make changes right away to make sure the final product meets quality standards. This cuts down on waste and the need for extra work.

• Predictive Maintenance: AI can tell when 3D printers need to be fixed or when certain parts are likely to break. AI algorithms can proactively plan maintenance by looking at sensor data and past performance. This keeps downtime to a minimum and print quality consistent.

• Material Selection: AI helps choose the best materials for a 3D printing project. It makes smart suggestions based on the properties of the materials, the cost, and the needs of the end user. This is especially helpful for fields like aerospace and healthcare where choosing the right materials is very important.

• Slicing Optimization: AI can make slicing software, which turns 3D models into instructions for printing, better. AI algorithms can make toolpaths better, cut down on print time, and use fewer support structures. This makes 3D printing faster and cheaper.

• Post-Processing Automation: AI automates and makes post-processing tasks better, like taking off support structures, sanding, and painting. AI-powered computer vision systems can find the parts that need post-processing and do what needs to be done.

• Supply Chain Optimization: AI can help make the supply chain for 3D printing better. It can keep an eye on stock levels, guess how much will be needed, and allow for just-in-time production, which cuts down on waste and storage costs.

• Design Help and Feedback: AI can help designers and engineers by giving them real-time feedback on their design choices, suggesting ways to make them better, and even giving them design options that can be 3D printed more quickly or with better performance.

• Personalization and Customization: AI-powered algorithms can help with personalized product design and mass customization. By looking at what users want and need, AI can make designs that can be 3D printed that are perfect for each customer.

• Collaborative Design: AI can help with collaborative design projects, where several people or teams work on a 3D printing project at the same time. AI can help with design integration and resolving conflicts.

AI is making 3D printing technology better and more efficient in many parts of the process, such as choosing materials, optimizing designs, and quality control. This combination of AI and 3D printing leads to new ideas and opens up new possibilities for additive manufacturing in many fields. AI will probably play an even bigger role in the growth of 3D printing as it continues to improve.Conclusion

As we said before, the progress made in 3D printing technology has caused a revolution in many fields, making things that seemed impossible possible. For businesses and individuals, a 3D printing service offers an accessible entry point to leverage this powerful technology. As technology gets better, it promises to make the future brighter and more creative.

Contact us to explore how 3D printing can bring your ideas to life. Whether you’re a business looking to innovate or an individual with a vision, we’re here to help you take the next step.

- Tagged 3D Printing, 3D Printing Company In Malaysia, 3D Printing Company Malaysia, 3D Printing Creations Malaysia, 3D Printing Designs Malaysia, 3D Printing Machines, 3D Printing Malaysia, 3D Printing Service Malaysia, 3D Printing Service Near Me, 3D Printing Services, 3D Printing Technology, 3D Printing Websites Malaysia, Custom 3D Printing Malaysia