Can You Mix Resins for 3D Printing? Here's What You Need to Know

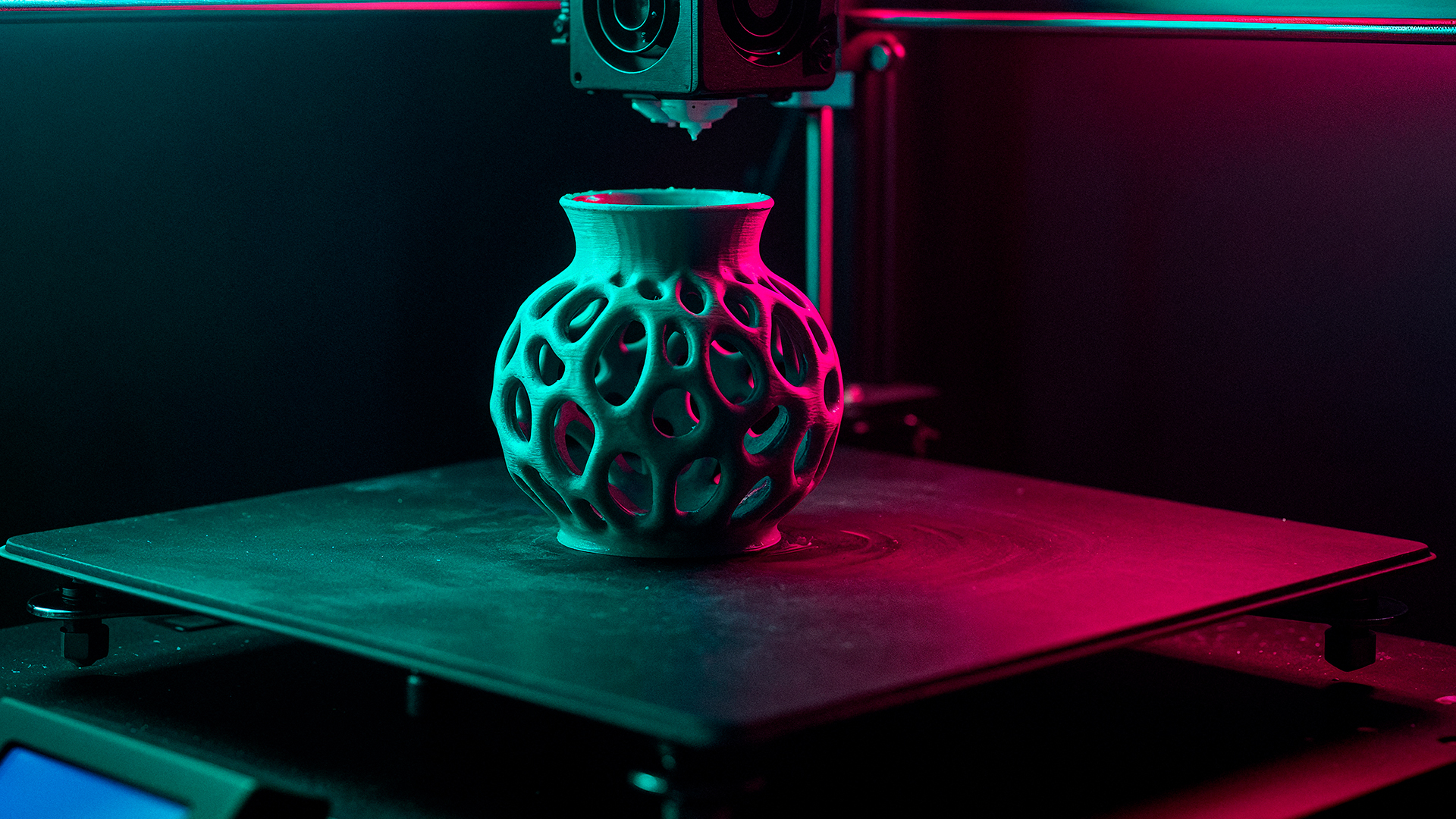

Ceramic 3D printing has come a long way since its early experimental days. It used to only be able to make simple designs and small-scale prototypes, but now it is the best choice for industries that need both artistic intricacy and mechanical performance. Combining traditional ceramic materials with current digital fabrication lets designers try with textures, shapes, and patterns that would have been hard to make by hand. As more people use this technology, 3D printing ceramic materials has changed to satisfy a wide range of purposes, from medical gadgets to fine art sculptures.

Mixing resin is one of the most intriguing new things in this sector. Users can change the colour, density, and surface smoothness of ceramic-infused resins by mixing them together. The technique is incredibly flexible, letting you try new things while keeping the structure intact. Ceramic 3D printing will keep growing in art, architecture, and product design as more printing technology and appropriate resins become available.

Table of Contents:

Why It Matters To Mix Resin In Ceramic Printing

Mixing resins is not only a fun experiment; it’s a great approach to changing how materials behave. Mixing ceramic resin for 3D printing can change how light goes through the resin, how sturdy the finished product is, and how the surface feels once it has cured. For example, mixing two resins that work well together can make a material that is both flexible and rigid, making items that are both durable and look good.

This method also lets users change the speed and viscosity of the curing process to make printing more accurate. A resin that cures more slowly may help layers stick together better, while a resin that cures more quickly may help with detail. But to combine resin, you need to know about chemistry, how temperature affects things, and the boundaries of each substance. If done correctly, the method makes items that are better than regular prints. If done wrong, though, it might make them brittle or have a bad surface quality. The secret is to test in tiny batches, watch what happens, and be consistent.

How To Get The Right Balance Of Resin

When finding the right resin mix for ceramics, you need to be patient and plan ahead when you 3D print. The hardness, colour tone, and curing period of each resin are different, which changes how it interacts with other resins. To make a good blend, you need to match these traits as nearly as possible. To begin, mix small amounts of two resins that work well together. Stir slowly until the mixture is smooth and even. This makes sure that the curing is even and lowers the chance of air bubbles appearing while printing.

The temperature and how the item is stored also have a huge impact on the result. To keep mixed resins from settling or separating, they should be used right after they are made. Doing short print testing before scaling up can help find problems before they get too big. Keeping track of your results after each attempt will make it easy to use the same mixtures in future projects. Over time, you’ll find a way to work that gets the most out of your supplies.

Mixing Resin Has More Benefits Than Just Colour

A lot of people mix resins to get the colours they want, but there are many other benefits to this process besides how it looks. Mixing can make 3D ceramic printing stronger against heat, impact, and bending. A resin that is a little more flexible can improve the printing process by absorbing stress, which lowers the chance of cracks or warping in designs with thin walls. Combining two distinct types of ceramic-based resins, on the other hand, can make finishes smoother, which means less work after the fact.

Mixing also makes it possible to do new things in fields like product design, industrial manufacturing, and architecture. Engineers may make parts that are strong, light, and long-lasting, while painters can try out new textures and types of painting. The most important thing is to think about resin mixing as an extension of design itself—a way to change both the look and the function of something equally.

Perfecting After Processing

The real beauty of ceramic 3D printing comes out after the printing is done. The printed model can get its final look by being sintered, glazed, or polished after it has been cleaned and cured. This is especially crucial when using mixed resins because the curing process might change the colour and smoothness of the surface. Putting on a glaze or clear coat helps smooth out these differences and make them last longer.

Sintering changes the printed resin into a thick ceramic structure that can handle high temperatures. If done well, this step keeps the accuracy and detail of the print while making the product stronger. Every part of the process, from choosing the resin to the post-processing, helps make a professional-quality ceramic piece that looks and works like conventional burned pottery, but with the added benefit of digital accuracy.

Trying New Things To Come Up With New Ideas

Mixing resin in ceramic resin 3D printing is a place where science and creativity come together. Every experiment teaches us something about how materials behave in certain situations, which helps us improve our methods and get consistently good results. More makers are trying out unique resin blends, so we should expect to see new textures, finishes, and hybrid materials come out.

This attitude of trying new things is leading to new ideas in many fields. The capacity to change the properties of resin gives designers unlimited freedom. For example, aerospace engineers can make lightweight parts, and artists can make complicated sculptures. Ceramic 3D printing will keep closing the gap between traditional art and cutting-edge engineering as the technology gets better.

Making Your Ideas A Reality

Working together, trying new things, and being precise are the keys to the future of 3D ceramic printing. Resin mixing gives you full control over both appearance and performance, whether you’re a designer trying to push the bounds of creativity or a factory looking for ways to make things more efficiently. You can make things that are both useful and attractive if you know how 3D printing ceramic materials work together.

If you want to learn more about mixing resin and 3D printing ceramics, contact us immediately to start your journey. We can work together to turn your creative vision into a real work of art made with care, precision, and new ideas.