All You Need to Know About Sand 3D Printing

Sand 3D printing allows for the creation of intricate moulds, core pieces, and architectural designs that would otherwise be difficult or expensive to create using traditional methods. This method employs precise layer-by-layer application of sand and glue to create buildings with complex shapes and superior performance. Sand printing is evolving beyond its traditional application in industrial casting to incorporate more sophisticated technologies such as full-color 3D printing. This rise is causing waves in the design and decoration industries, affecting markets in Malaysia and around the world.

Sand printing is appealing because it mixes ancient and new technology in a unique way that no other approach does. For thousands of years, traditional sand casting has proven to be effective. However, current additive techniques offer digital precision, fewer limitations, and far shorter lead times in terms of complexity and speed. The industrial sector is evolving and embracing full-color 3D printing and sand-based technologies. This provides new opportunities for development, production, and creative ventures.

Table of Contents:

How Sand 3D Printing Works and Why It Matters

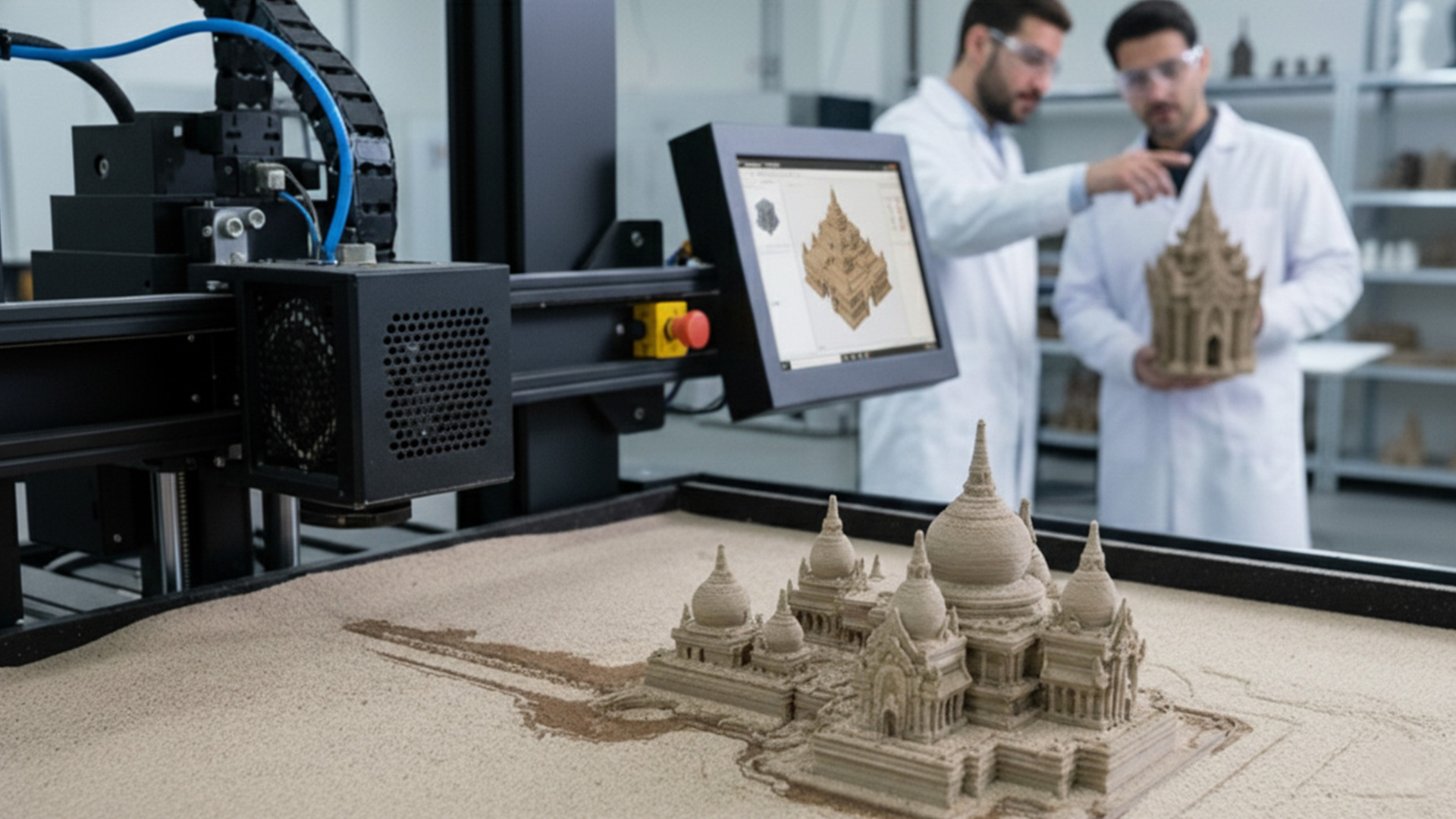

The method starts with a computerised 3D model that designers have meticulously sculpted into thin layers and transported to a binder-jetting printer for precision printing. To achieve the desired shape, the system carefully deposits a specific layer of sand and selectively uses a liquid adhesive. When the printing finishes, workers remove the excess sand, resulting in a flawless mould or core ready for the next phase. This improvement makes it considerably easier to transition from design to mould, and it performs better than traditional casting techniques.

Sand in additive manufacturing allows foundries and designers to create convoluted internal routes, complex undercut geometries, and highly detailed surfaces while minimising assembly requirements. Previously, these characteristics were constrained by tooling, mould design, or a scarcity of labour. 3D sand printing in Malaysia can help manufacturers and designers work faster, waste less, and be more adaptable. This technology is quite handy when you need to see a product concept or architectural model in full colour.

Broader Applications for 3D Printing Products Malaysia and Beyond

Sand 3D printing, like traditional foundries and industrial casting, is gaining popularity in Malaysia and other areas where customisation and speed of production are vital. Manufacturers may now swiftly create sand cores for parts in the aerospace, automotive, and architectural domains, speeding up the design iteration process. Making single-step moulds or cores reduces lead times and the risks associated with bringing new items to market.

In the field of design, sand prints enhanced with vibrant full-color 3D printing techniques stand out as intriguing prototypes, immersive models, or even stunning finished ornamental pieces. Architects, designers, and enterprises in Malaysia use these visuals to communicate ideas to clients and stakeholders in ways that static sketches and traditional models cannot.

The Role of Material Choice in Full-Color and Sand Printing

Choosing the correct material system for sand printing is critical for achieving optimal outcomes. The sand used in these activities must be able to withstand high temperatures, maintain its shape, and function with the subsequent casting or polishing processes. The ultimate outcome is heavily influenced by the binder system, grain size, and post-processing techniques. Businesses may now obtain more accurate and realistic images, even in sand-based forms, thanks to the completion of the manufacturing chain in full-color 3D printing.

Thanks to improved materials and process control, Malaysian service providers can now create 3D printing products that meet the expectations of clients who seek both practicality and aesthetics. Physical prototypes that combine sand printing with full-color output may accurately depict the intended design. This ensures the design’s integrity and visual quality across the entire process, from concept to execution.

Moving Forward with Innovation

This technology is more than just a new means to produce things; it represents a significant step towards more adaptable, customised, and visually appealing manufacturing methods. Businesses in Malaysia and around the world are discovering new ways to be creative and produce outstanding results by combining sand-based additive processes with full-color 3D printing.

Are you ready to discover out how these new technologies can improve your next project? Contact us right away so we can help you turn your vision into a reality, from moulds and cores to beautiful product prototypes.