How 3D Printing Is Revolutionizing The Fashion Industry: Innovations & Future Trends

3D printing service is changing how fashion is designed and made all over the world. Local 3D printing services now let designers try out shapes and textures that used to be impossible. It’s easier than ever for designers to turn bold ideas into clothes.

Why Should You Opt For A 3D Printing Service?

Picking a 3D printing service turns ideas into real things quickly and cheaply. You can easily get started with local 3D printing services and 3D printing service online. Your idea comes to life with the help of 3D printing service companies and Malaysia 3D printing service.

How 3D Printing Makes Complex Jewelry Design More Accessible

Jewelry has always echoed art, culture, and craftsmanship. Jewelry making was an art requiring mastery and many years of training. Steady hands, specialized tools, and patience were needed with intricate patterns

Best Things to 3D Print and Sell for Profit

With the 3D printing industry being the fastest-growing industry in the world, Malaysia is no stranger to this benefits. The population is now searching for 3D Printing Products Malaysia for reasonably priced custom solutions.

Complete Guide to Metallic 3D Printing Filaments

Metallic 3D Printing isn’t perfect yet when it comes to making metal products, but it can make 3D prints that look and feel like metal with the help of metallic 3D printing filaments. They help make things like jewellery, busts, sculptures, and museum replicas.

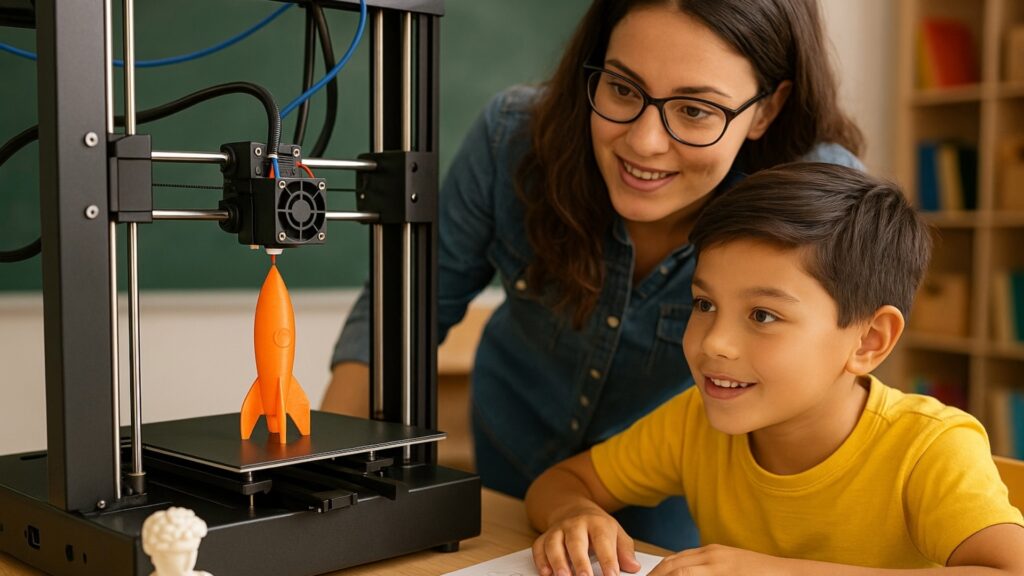

How 3D Printing is Transforming Education

How 3D Printing is Transforming Education With the use of tools like Autodesk Fusion, 3D printing helps children learn by making challenging topics easier to understand, promoting creativity, and getting them ready for careers in the future. Table of Contents: What Does It Mean to Make Something in 3D? How 3D Printing is Used in […]

What are the Benefits of Adopting Metal 3D Printing? Business Side and Technical Benefits

What are the Benefits of Adopting Metal 3D Printing? Business Side and Technical Benefits Manufacturing has undergone a transformation with Metallic 3D Printing. Compared to previous manufacturing techniques, this more flexible technology enables producers to create complex metal parts more quickly, easily, and affordably. When manufacturers properly implement metallic 3D printing, they eliminate the need […]

The Rise of 3D Printing in Metal Manufacturing

3D metal printing has become the next big fabrication technique, set to revolutionize traditional methods. At our 3D Printing Company, we’ve worked in the metals industry for years, and this technology excites us like few others.

The Future of Medical 3D Printing: Innovations in Healthcare Technology

There are more brave new ideas than ever because of new technologies in healthcare. 3D Printing in Medical is transforming how we diagnose, treat, and care for patients. This in-depth study looks at the many present uses of medical 3D printing, how technology keeps becoming better, and how it could alter healthcare in the future.

Analysis of Aluminium Alloy in 3D Printing Industry

Aluminium 3D printing have signalled a noticeable change in demand for metal additive manufacturing materials due to the increased usage of aluminium alloys. Aluminium alloys now rank as the most popular alloys after steel, titanium, and nickel. By 2030, experts expect them to become the third most popular alloy and make up around 20% of all metal AM material shipments.