What is SLS 3D Printing? A Guide to Selective Laser Sintering

Selective laser sintering (SLS) 3D printing is a powerful way to make things by adding materials together with a laser. You’ll learn how 3D Printing SLS works in this guide. You’ll also learn about the benefits of SLS for quick prototyping and small-scale production, as well as the many materials and options available to meet your needs.

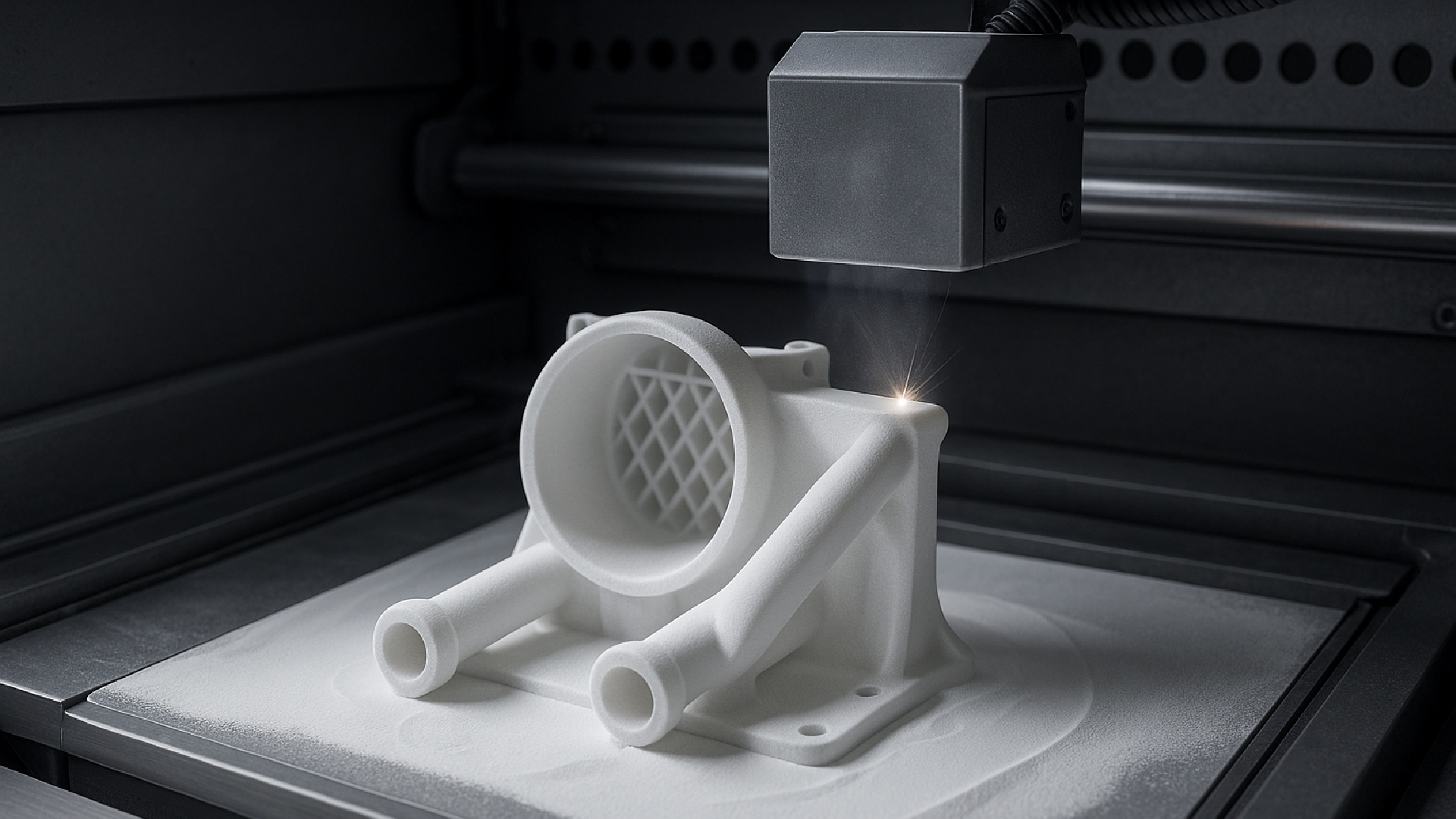

Additive manufacturing includes selective laser sintering (SLS), which is a type of powder bed fusion. In the SLS 3D Printing process, a powerful laser selectively sinters particles of thermoplastic polymer powder, layer by layer, to make a solid, working part. These materials are used in granular form and have great mechanical properties.

SLS is very useful because it can do so many things. If you want to avoid the high costs of tooling up front, this is the best option. SLS is a very cost-effective way to make long-lasting, high-quality parts in small to medium quantities, usually less than 1,000 units. This lets you test fit, function, and performance before you buy production tools.

Our 3D Printing Service at Scale Model 3D Printing can be used for both functional prototyping and small to medium production runs of polymer parts that will be used.

What is The Process of SLS 3D Printing?

With SLS 3D printing, a powerful laser selectively sinters small particles of polymer powder, fusing them together to make solid layers. SLS scans and sinters the whole cross-section of each layer, which makes parts that are strong and completely solid. This is different from other 3D Printing Designs.

This is how it works:

• Preheating: The system preheats the powder storage and build areas to just below the melting point of the polymer.

• Layering: A re-coating blade spreads a thin, even layer of powder across the build platform.

• Laser Sintering: A CO₂ laser scans and sinters the shape of the layer, fusing powder particles exactly where the part’s geometry requires.

• Build Layer by Layer: After each layer, the platform moves down slightly and the system adds a new layer of powder. This continues until the part forms completely.

• Cooling Phase: Once the print finishes, the machine allows the build chamber to cool before operators remove the parts. This step can take up to 12 hours.

• Post-Processing: Operators remove unused powder that surrounds the printed parts using compressed air or media blasting. After this, the parts are ready to use or refine further.

Is SLS 3D Printing Good for Making Quick Prototypes?

Yes, SLS 3D printing provides a great method for quickly creating prototypes, especially when you need polymer parts that function reliably. One of the best things about SLS lies in its ability to produce very precise parts with complex geometries and no support structures. SLS ensures that parts have consistent mechanical properties throughout, which means prototypes can come very close to the quality of final-use parts. That’s why this method suits concept models, functional testing, and pilot production with confidence.

Is It Possible to Use SLS 3D Printing for Small-Scale Production?

Absolutely. SLS offers a scalable and flexible solution for low-volume production. When you need fewer than 1,000 parts and want to avoid tooling costs, SLS offers a more economical alternative to injection moulding. You can design freely, and SLS accommodates complex shapes, various finishes, and different lead times. It supports everything from pilot production to small-batch manufacturing without sacrificing quality or function.

What is The Process of an SLS 3D Printer?

Set Parameters and Layer Height

Most manufacturers ship SLS 3D printers with factory-set parameters to ensure consistent output and user-friendly operation. A typical layer height ranges between 100 and 120 microns, offering a balance between speed and surface detail.

No Need for Support Structures

One of the best things about SLS is that it doesn’t need any support structures. The unsintered powder around the parts naturally holds them in place while printing, which makes it possible to create complex shapes and internal features that would be hard or even impossible to do with other 3D printing methods.

Using the Build Volume Wisely

It is very important to optimise the build volume, especially for small production runs. The re-coating step is what really determines how long it takes to print, since laser scanning is so quick. The printer processes the same number of layers, whether it prints one part or several. Because of this, build chambers are often packed well before printing starts, which can change the lead time.

Adhesion of Layers

SLS builds parts with excellent layer bonding, which gives the final parts nearly isotropic mechanical properties. This makes them ideal for functional prototypes and final-use components.

SLS parts deliver solid tensile strength, though they remain more brittle than injection moulded parts due to internal porosity.

Shrinking and Warping

When SLS parts cool, they usually shrink by 3 to 3.5%. This is taken into account when designing and building. But warping can still happen, especially on big, flat surfaces. To help reduce distortion:

• Put flat features in a vertical position

• Make wide surfaces thinner

• To relieve internal stress, add ribs, fillets, or cutouts.

These changes can also cut down on the amount of material used and the cost of the whole part.

Too Much Sintering

The laser’s radiant heat can cause nearby powder to fuse together by accident, which can make small details like holes or slots less clear. In general:

• There should be at least 0.8 mm of space between the slots.

• The holes should be at least 2 mm wide.

Powder Removal

SLS can easily make parts with internal cavities because they don’t need any support structures. Hollowing out parts can save a lot of money and weight, but the unsintered powder that is left over must be removed through escape holes.

We suggest adding:

• At least two holes to escape

• 5 mm is the smallest hole diameter.

If a part needs to be stiffer, it can be left hollow with no holes for escape. The packed powder stays inside, which adds weight and strength without adding time to the build. You can add a honeycomb lattice inside, which is similar to FDM infill patterns, to make the strength-to-weight ratio even better.

What Kinds of Things Can be Printed with SLS?

Polyamide 12 (PA 12), also known as Nylon 12, is the most common material used for SLS 3D printing. People like this material because it has a great balance of mechanical properties, is cheap, and is easy to work with.

Polyamide 11 (PA 11) and PEEK are two other materials that are available, but they are not used as often because they are more expensive and have more specific uses.

You can enhance polyamide powders by adding fillers such as carbon fibre, glass fibre, or aluminium. These additives increase stiffness, heat resistance, or wear resistance. However, they also make the parts more brittle and anisotropic (where properties depend on print direction).

What Choices do You Have for SLS Post-Processing?

SLS parts usually have a rough, powdery surface that picks up dirt easily. Post-processing methods can greatly improve their appearance and function:

• Media polishing: It makes the surface smoother and better.

• Dyeing: This gives the part colour and comes in a range of shades.

• Spray painting and lacquering: Adds shine and extra protection.

• Watertight coating: This seals the part so that it is less likely to get wet.

• Metal plating: Gives a metallic finish that makes it stronger and better at conducting electricity.

What Are The Benefits of SLS 3D Printing?

Most SLS 3D printed parts have a rough, powdery surface that can get dirty easily. There are many ways to improve the look and function of these parts after they have been made. You can greatly improve the look, durability, and surface finish of your parts with these methods:

• Media polishing: It makes the surface smoother and better.

• Dyeing: This gives the part colour and comes in a range of shades.

• Spray painting and lacquering: Adds shine and extra protection.

• Watertight coating: This seals the part so that it is less likely to get wet.

• Metal plating: Gives a metallic finish that makes it stronger and better at conducting electricity.

What Are The Bad Things About SLS 3D Printing?

There are some downsides to SLS, even though it has a lot of benefits:

• Longer times to get things done: At the moment, industrial-grade SLS systems are the most common. This means that they may take longer to get than other 3D printing technologies like FDM and SLA.

• Surface finish and porosity: SLS parts often have a rough, grainy surface and holes inside them. If a smooth finish or waterproofing is needed, they may need to be post-processed.

• Warpage and oversintering are possible: Large, flat surfaces and small holes may not print as accurately because of warping or oversintering, which can cause the final part to have distorted features.

Best Practices for SLS

Is SLS 3D printing the best way to make your part or project? Here are some important rules of thumb to help you make your choice:

• Versatility of Materials: SLS can make functional parts from many different types of engineering plastics, but Nylon (PA12) is the most common.

• Most SLS systems have a standard build volume of 300 x 300 x 300mm, which is good for small production runs and medium-sized parts.

• Mechanical Properties: SLS parts have strong mechanical properties and behave isotropically, which means they work the same way in all directions. Additive-filled PA powders, like carbon-fiber or glass-filled materials, are available for parts that need special properties, like better strength or thermal properties.

Contact us to explore how our 3D printing solutions can support your next project. Whether you’re prototyping a new design or preparing for production, we’re here to help you choose the best technology, materials, and processes. As a trusted provider in 3D Printing Malaysia, we’re ready to guide you through the next steps—just share your requirements with our team.