Why is 3D Printing SLS for Production Now More Affordable Than Ever?

SLS 3D Printing can produce items at amazing speeds with a level of detail that is on par with injection moulding. However, traditionally, the technology has been plagued by unaffordable prices. Thanks to technology advancements, it is now more affordable and accessible than ever.

Any business or workshop may achieve industrial-level productivity with the help of new printers, software, and other technology. These days, even tiny businesses can print precise, long-lasting parts at affordable prices using 3D Printing Service providers or in-house setups.

Continue reading to find out how SLS 3D Printing is now more inexpensive than ever for any firm, especially SMEs, thanks to the newest equipment and tools

Table of Contents:

The Demands of SLS 3D Printing Might Be High

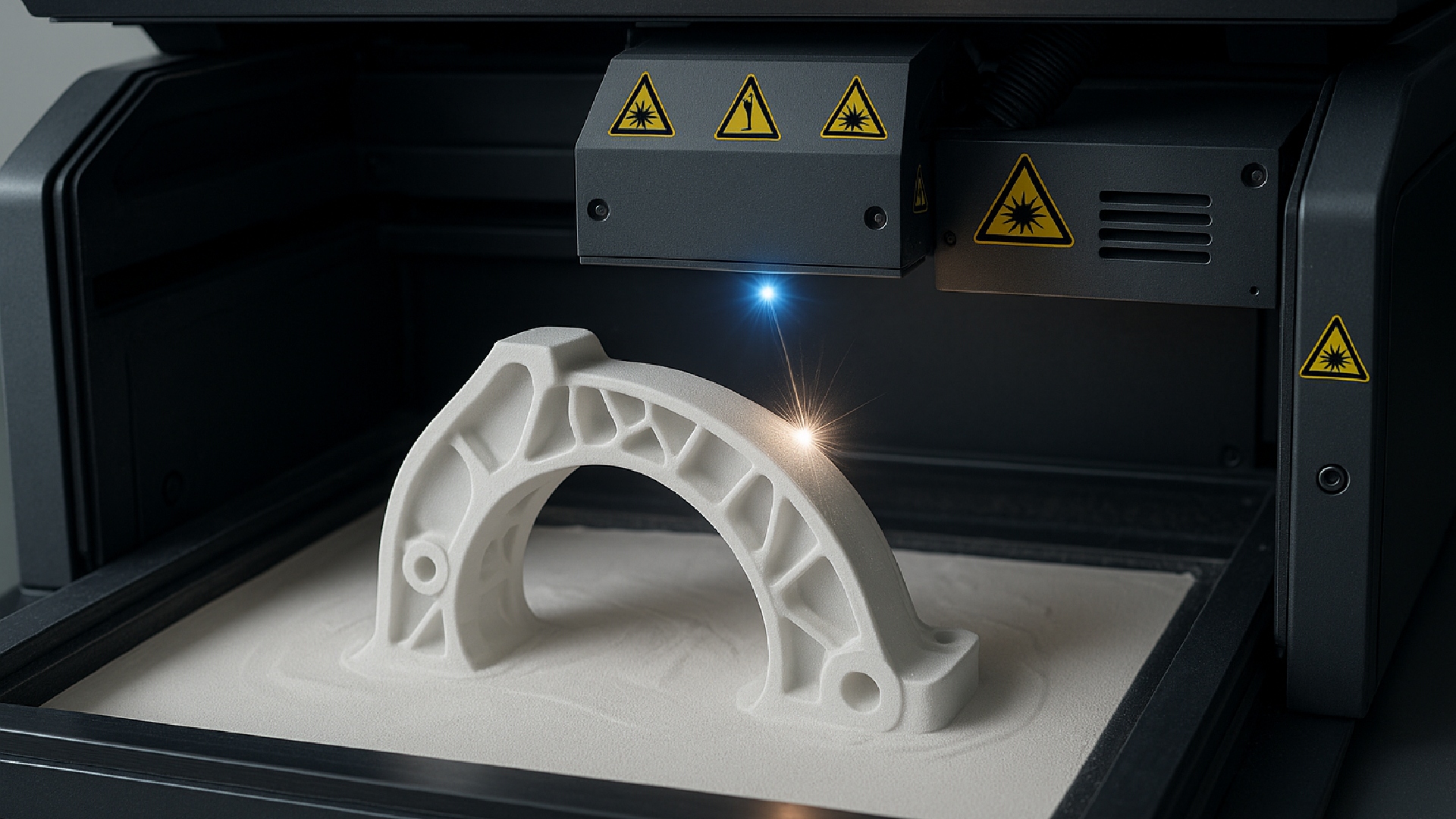

SLS 3D Printing serves as a potent technology that produces useful components for final uses. The printers use powerful laser beams to melt thermoplastic granules into solid things.

A variety of demanding industries, including the medical, aerospace, and automotive sectors, widely use SLS. It provides users and operators with a wide range of advantages, such as:

• Production Speed: SLS ranks among the fastest 3D printing technologies on the market. Depending on the equipment, multi-laser systems can manufacture dozens of pieces in a few hours, though the precise speed varies.

• High Productivity: You create less waste the more parts you construct, so SLS printers push you to maximize productivity. Furthermore, compared to other additive manufacturing techniques, SLS offers one of the greatest ROI rates.

• Design Freedom: Unlike many other technologies, SLS components don’t require supports. You can use the loose powder and other components in the print chamber to support printed components and produce incredibly complicated geometries, such as 3D Printing Designs like interlocking pieces.

• Low Waste: After a print operation, you can recover and reuse up to 70% of the loose powder. Powder recycling reduces both material waste and material expenses.

Despite the advantages, SLS 3D Printing has historically demanded high costs and requirements. Only the biggest companies have been able to afford the machines due to their size and price.

Older SLS printers also required operators with specific skills, and the cost of materials remained considerable. These factors have created accessibility problems for SLS 3D Printing.

Print SLS Parts Accurately and Quickly

However, SLS technology has developed quickly in recent years, and more compact and reasonably priced equipment are now available. Formlabs Fuse 1, at the forefront, has revolutionised 3D Printing SLS.When Formlabs first released the Fuse 1 in January 2021, the device changed the game. It offered a reasonably priced, benchtop printer capable of producing parts with the same robustness and quality as its more expensive, industrial-sized relatives.

Formlabs has now updated the Fuse family. The Formlabs Fuse 1+ builds upon the framework established by its predecessor.

The Fuse 1+ outpaces the already quick original Fuse 1. The upgraded printer features a powerful 30W laser and an improved galvanometer for better printer head movement. Because of this, the Fuse 1+ can print at up to twice the speed of its predecessor.

Fuse 1+ still creates products with excellent durability and precise, sharp detail, and now it can employ a wider range of materials. Thanks to a new powder handling technology and an inert nitrogen gas chamber, the Fuse 1+ can print with Nylon 11 and Nylon 12, as well as powders reinforced with glass and carbon fibre.

The printer’s software and touchscreen interface simplify use. It quickly creates parts with mechanical qualities suitable for final application. Companies of various sizes may quickly and affordably realise complex, demanding part designs.

Utilise the Most Up-to-Date Software Tools

A good printer is not the only requirement for SLS 3D Printing. To guarantee effective print runs, each component needs to be carefully prepared. Businesses may increase productivity and streamline their 3D Printing Malaysia workflows with the use of sophisticated and highly automated print preparation software.

In recent years, software tools for additive manufacturing have made significant progress alongside physical printers. With its line of upscale 3D printing solutions, Materialise is one of the more well-known software developers in the industry.

Materialise Magics, for instance, is a sophisticated, intelligent data preparation program for additive manufacturing. Because the solution is technology-neutral, it may be used with any 3D printer, including SLS devices.

A special Sinter Module add-on for SLS printers in this industry-standard software allows for quick, automated print preparatory procedures to increase throughput and print speeds. Many of the intricate and time-consuming steps involved in SLS print preparation, like part nesting, collision detection, and orientation optimisation, are automatically handled by Materialise Magics. Prior to actual printing, it may mimic the print process, enabling you to identify and address any potential problems before wasting material.

For users of 3D printers, Materialise also provides additional software options. Among the products in their inventory are Build Processor, which simplifies data transfer between PCs and printers, and Materialise 3-Matic, a CAD design optimisation tool.

Boost Your SLS 3D Printing Business

By making SLS printing quicker and more widely available, these and numerous other advancements have altered the character of the AM business. Now, any organisation that needs production 3D printing may easily access what was once an exclusive technology that required significant financial, temporal, and spatial expenditures.

SLS printing has become more accessible thanks to contemporary small and reasonably priced SLS printers like the Formlabs Fuse 1+. Even tiny enterprises can create new cash streams with these equipment, which can be installed in any workshop. Together with cutting-edge software and post-processing options, they have increased the speed and affordability of SLS technology.

Innovation has not slowed down in pace. Although we are unsure of what the future holds, there is reason for excitement. SLS 3D printers, meanwhile, are still removing obstacles in the field of additive manufacturing.

Contact us to learn how our team can support your production goals with cutting-edge technology and expert guidance. Whether you’re a small business or an established manufacturer, we’re here to help.